Current location:Home / News / Industry information / Cold Heading Machine Prevents Workpiece Quenching and Mold Thermal Shock

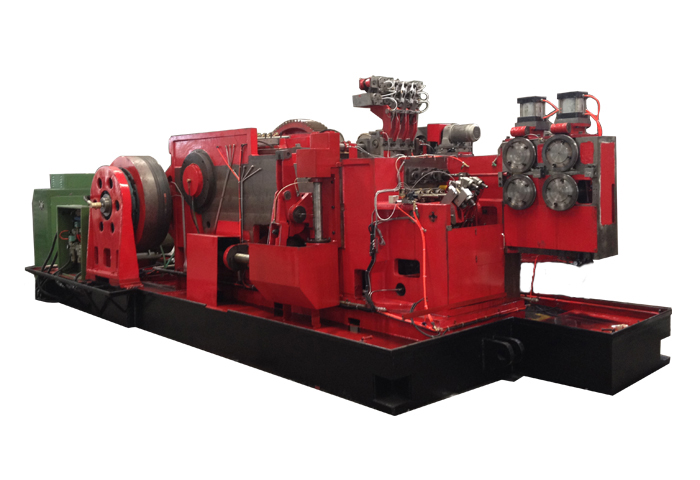

The cold heading machine controls the temperature and the temperature gradient caused by the heat loss of the workpiece during processing to reduce the processing deformation, and plays the role of heat dissipation and insulation to prevent the workpiece from quenching and the thermal shock of the mold

The types of fasteners produced by the cold heading machine include bolts, studs, screws, nuts and self tapping bolts, which are a kind of fasteners consisting of head and screw (cylinder with external thread). It is used to put two through holes. This connection is called bolt connection.

Popular products

Recommended News

Features of Multi station Cold Heading Machine and Precautions in Use2022-10-31

After laser disk or bar tapping, the multi station cold heading machine automatically assembles various hexagon nuts, namely light standard hexagon nu…

Processing technology, mechanism and working principle of automatic cold heading machine2022-10-31

The automatic cold heading machine is a special equipment mainly used for the mass production of nuts, bolts and other fasteners. The earliest cold he…

How to debug multi station cold heading machine?2022-10-21

How to debug multi station cold heading machine? And precautions for operating the multi station cold heading machine. 1. Press and hold the emergency…

Introduction to Cold Heading Machine Learning2022-10-21

Introduction to cold heading machine. 1. Check that the knife plate, cutting knife bar, punch, die, etc. should be intact without cracks, installed co…

Full system solutions for quality machinery manufacturers

Full system solutions for quality machinery manufacturersAll product pictures and publicity pictures of this website belong to us. No individual or organization is allowed to use them, and any embezzlement must be prosecuted.

Tel:0577-86266681Tel:0577-86125986mobile phone:13806699071E-mail:tianweimachine@126.comAdd: Haixi Industrial Park, Pingyang County, Wenzhou, Zhejiang

Service hotline

13806699071

We warmly welcome your consultation, and we will provide you with satisfactory mechanical solutions